Laser Lab

Lasers provide extraordinary characteristics of high brightness, high directionality, high coherence, high monochromaticity, and unique spatial and temporal distributions. These features make lasers well-suited to high accuracy, high quality, high efficiency, non-contact materials processing and manufacturing, with high controllability and ease of automation. High-power lasers beam can be focused to a power density up to 10-12 W/cm2. Material processing by such laser beams is well established as an advanced manufacturing technology and includes a large variety of processing technologies and research areas, such as:

|

|

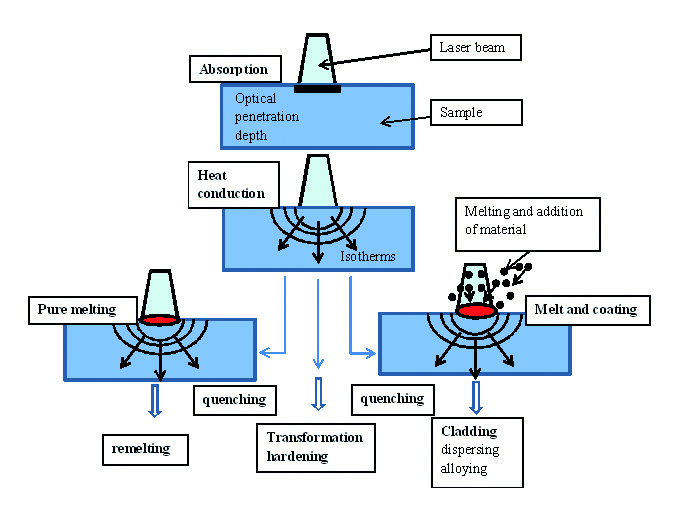

One of the processes in which we are interested is the laser cladding which is a process whereby a new layer of material is deposited on a substrate by laser fusion of blown powders or pre-placed powder coatings. Multiple layers can be deposited to form shapes with complex geometry. The use of in-situ synchrotron X-ray diffraction during cladding process enables us to follow the evolution of the microstructure and phases as function of the cladding parameters such as:

- laser power density

- beam spot size

- traverse speed

- power flow rate

- laser beam absorption.

Cladding materials are had facing allows powders (Co-based, Ni-based and Fe-based plus various carbides, those of the substrates are cast iron, mild steel, alloyed steel, non-ferrous metals and son) the working principle of the laser surface treatments which involves the absorption and then heat conduction.

Laser Lab. Experimental Setup

The laser system (for in-situ and ex-situ experiments)

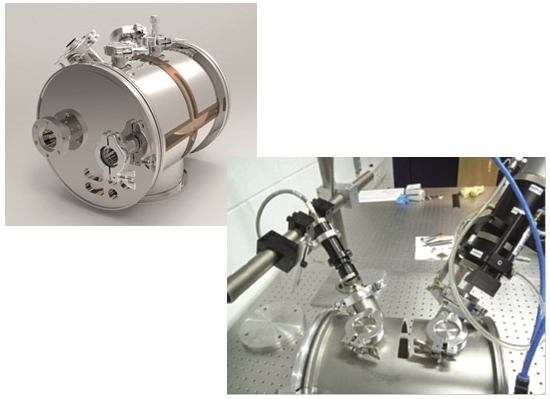

| At the NANO beamline we have a Fiber-coupled Diode Laser LDF 600-6000 VG 4L, consisting of a diode laser head (water cooled), integrated in the laser power unit. The laser signal can travel through an optical fiber cable of 600 μm and 5 m. A second fiber cable of 600 μm and 20 m goes to the Nano1 experimental hutch for in-situ experiments in the diffractometer with the synchrotron radiation. The laser unit works in the 900-1030 nm wavelength rage. It has a power stability of <+-2% at a cooling water temperature of ΔT<1 °C, the beam quality is the 66 mm mrad FWHM, the maximun power that we can have is 6KW. Additionally, we have a visible 600-700 nm laser pilot to align and visualize the laser spot position. |

|

|

The chamber and the temperature control system in the laser laboratory we can work in vacuum or in controlledatmosphere (Ar, N2,He, etc.). We have the possibility to install the chamber in the diffractometer for the in-situ experiments with the synchrotron radiation in the Nano1 Hutch or work in the laser laboratory for the ex-situ experiment. The sample is positioned inside the chamber in a motorized goniometer for stress analysis investigation and a X-Y-translation stage to scan the laser beam onto the sample during the cladding process. The laser process is controlled by two color pyrometer. |

| name | function | |

|---|---|---|

| Bauer, Sondes | Deputy Head of Department, Beamline Scientist | sondes bauer ∂does-not-exist.kit edu |