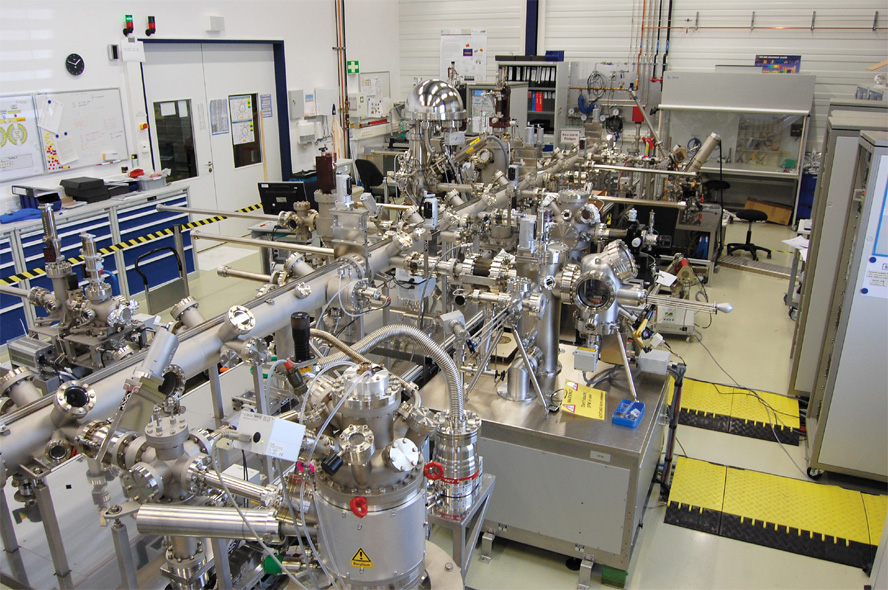

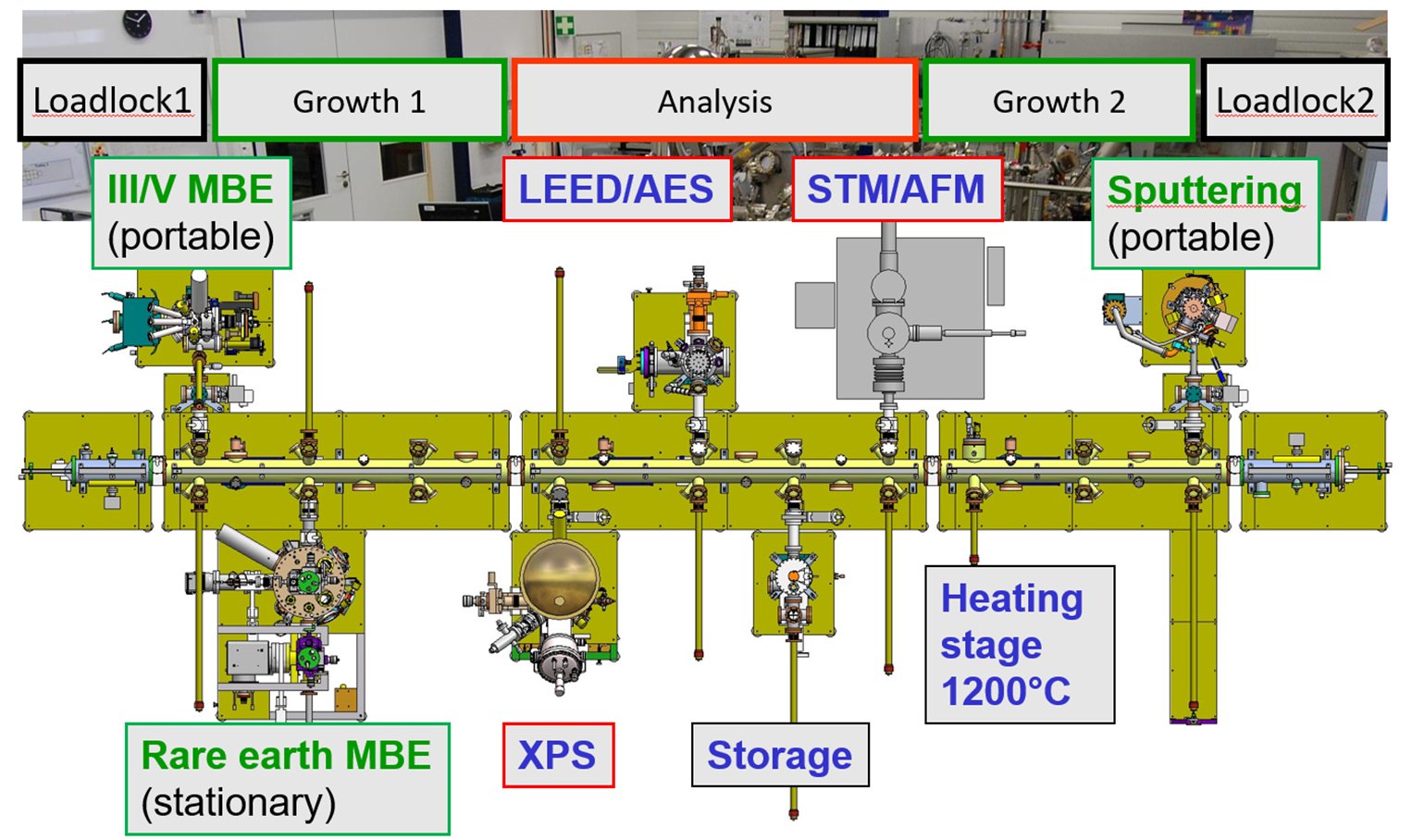

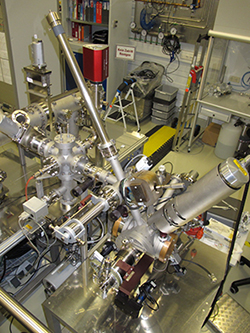

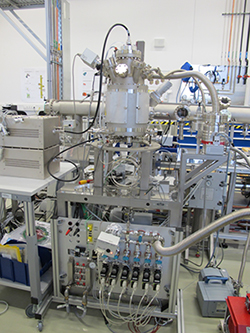

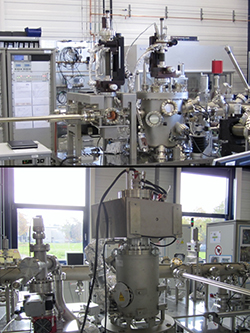

In the UHV analysis lab, samples can be analyzed by several standard surface characterization methods including spectroscopical methods (XPS and AES), diffraction methods (LEED and RHEED) and scanning microscopy (AFM and STM). Here, an overview over the methods is given. As an example, measurements of a gold single crystal are shown.

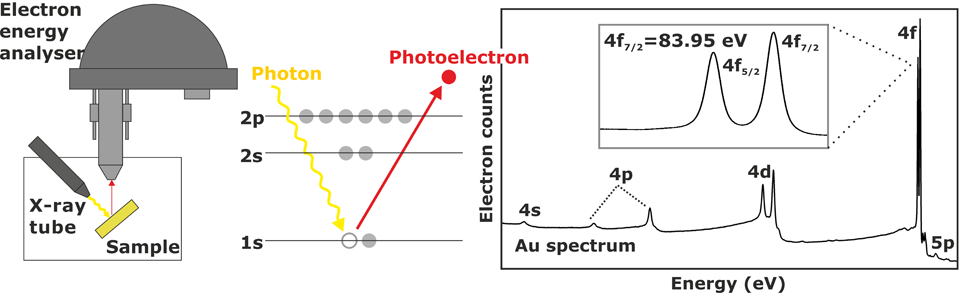

XPS - X-ray Photoelectron Spectroscopy

X-ray photoelectron spectroscopy gives information about the chemical composition of a sample within the topmost 2 nm. The sample is illuminated by soft X-rays. Photoelectrons are emitted, giving information about the binding energies of the atoms.

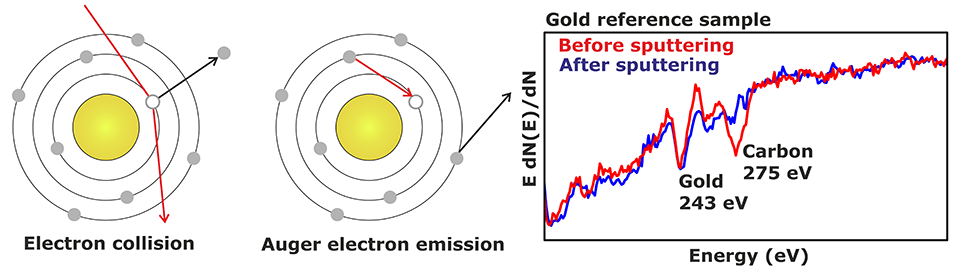

AES - Auger Electron Spectroscopy

Auger electron spectroscopy is another method to get information about chemical composition. Auger electrons are emitted from atoms, giving information about binding energies. One application of the method is to check a sample for surface contaminations, e.g. after contact with air.

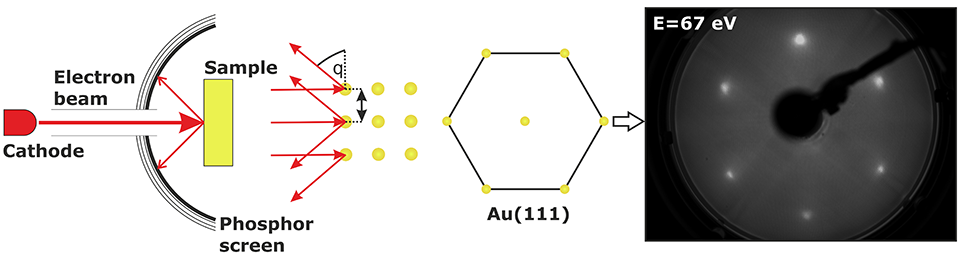

LEED - Low Energy Electron Diffraction

Low energy electron diffraction gives information about the atomic ordering of a material, by bombarding it with a beam of low energy electrons. The pattern of the structure, created by the diffracted electrons; is shown on a screen.

RHEED - Reflection High Energy Electron Diffraction

Reflection high energy electron diffraction is another method to examine the crystalline structure of the surface. Streaks indicate a smooth surface.

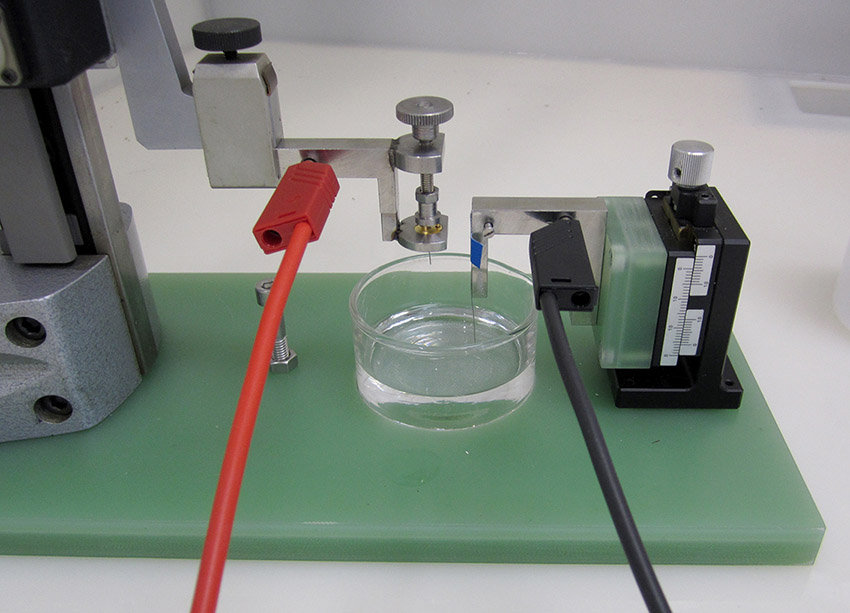

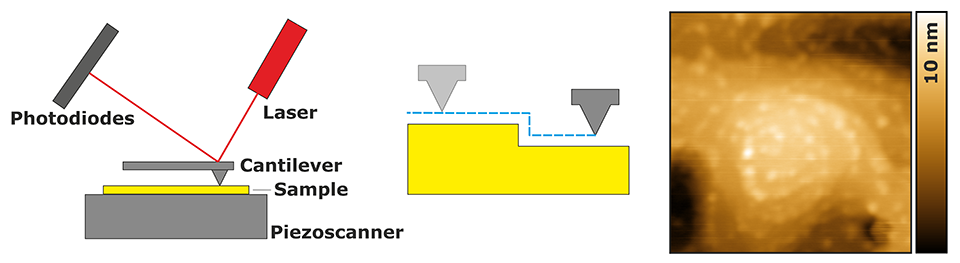

AFM - Atomic Force Microscopy

An atomic force microscope is a high-resolution scanning microscope which gives information about the surface morphology of a material on the atomic scale. The measured signal is the bending of a cantilever which is related to the force between a tip and the sample.

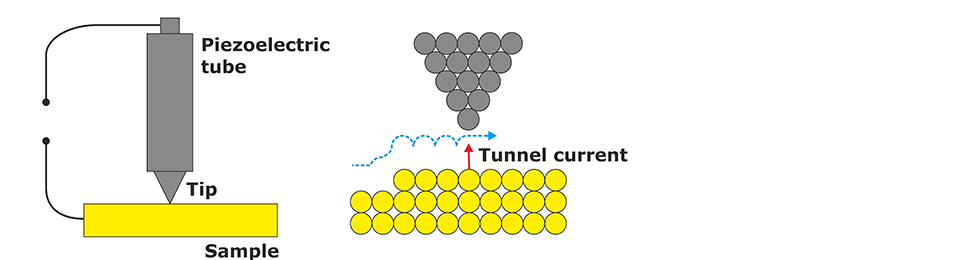

STM - Scanning Tunnel Microscopy

Another method for imaging surfaces is the scanning tunnel microscopy. The measured signal is a tunnel current between a tip and the sample.