PN-Reduktion

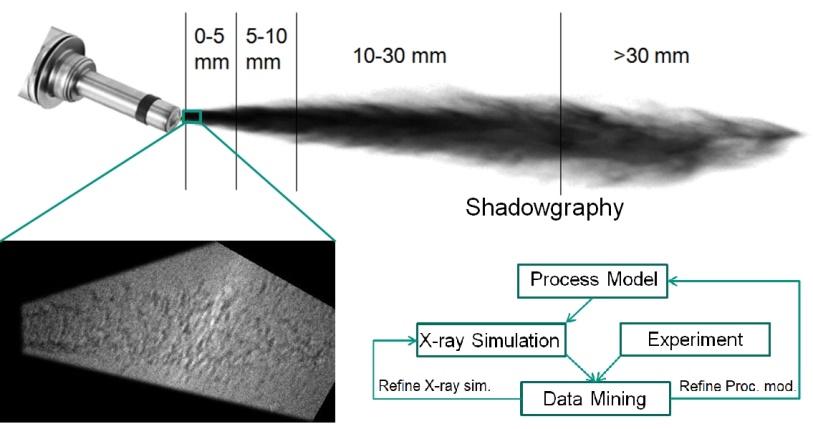

The aim of PN-Reduktion is the development of improved efficiency environmentally-compliant engines by combining low-CO2/NO/NO2 emmission motors with optimized fuel-injection technology to reduce particle emission by about 50% compared to current values. A multidisciplinary approach is required to understand the interplay between the large number of parameters involved. A specific aspect of the injection process is the transition between the internal flow characteristics at the injection nozzle exit and the subsequent spray formation.

|

Using high-speed X-ray radiography and shadowgraphy it is foreseen to characterize the physical development of fuel spray during its development and to correlate these data to flow-simulation models. For this a purpose-built mobile spray-injector chamber with an integrated high-speed camera setup will be realised. |

Correlating high-speed X-ray image data and model simulations under varying experimental conditions will permit optimisation of critical process parameters as a contribution towards improved design of the injection-nozzle system.

Project partners

- Continental Automotive GmbH

- Lehrstuhl für Technische Thermodynamik (LTT), FAU Erlangen

- Laboratory for Applications of Synchrotron Radiation (LAS), KIT

PN-Reduktion is funded by the Federal Ministry for Economic Affairs and Energy (BMWi) under the contract number 19I17011C

Publications

Indirect detector for ultra-high-speed X-ray micro-imaging with increased sensitivity to near-ultraviolet scintillator emission Lukić, B.; Rack, A.; Helfen, L.; Foster, D. J.; Ershov, A.; Welss, R.; François, S.; Rochet, X. 2024. Journal of Synchrotron Radiation, 31 (5). doi:10.1107/S1600577524007306

The influence of superheated injection on liquid and gaseous flow field of an experimental single-hole gasoline direct injection injector. Bornschlegel, S.; Conrad, C.; Durst, A.; Welss, R.; Wensing, M.; Olbinado, M.; Helfen, L.; Baumbach, T. 2021. International journal of engine research, 22 (2), 592–605. doi:10.1177/1468087419858464