Correlation of phase composition, chemical composition and microstructure in crystalline chromium aluminium nitride hard coatings

- Date: 2018

-

Magnetron-sputtered CrAlN coatings are widely used for industrial hard-coating applications. They have a high temperature stability, wear resistance and hardness. These favourable characteristics are related to the high Al content of

, which theoretically can be reached in a cubic single-phase solid solution (Mayrhofer et al., 2008

, which theoretically can be reached in a cubic single-phase solid solution (Mayrhofer et al., 2008  ; Rovere et al., 2010

; Rovere et al., 2010  ; Zhou et al., 2013

; Zhou et al., 2013  ).

).The crystalline phases depend on the Al content: at low Al content, a cubic mixed phase forms; at high Al content a hexagonal phase is found. In between, coexisting face-centered cubic (f.c.c.) and hexagonal close packed (h.c.p.) phases are observed. The solubility limit reported for Al in a single cubic phase varies significantly, indicating a strong influence of extrinsic material properties on the phase formation (Rovere et al., 2010

).

).

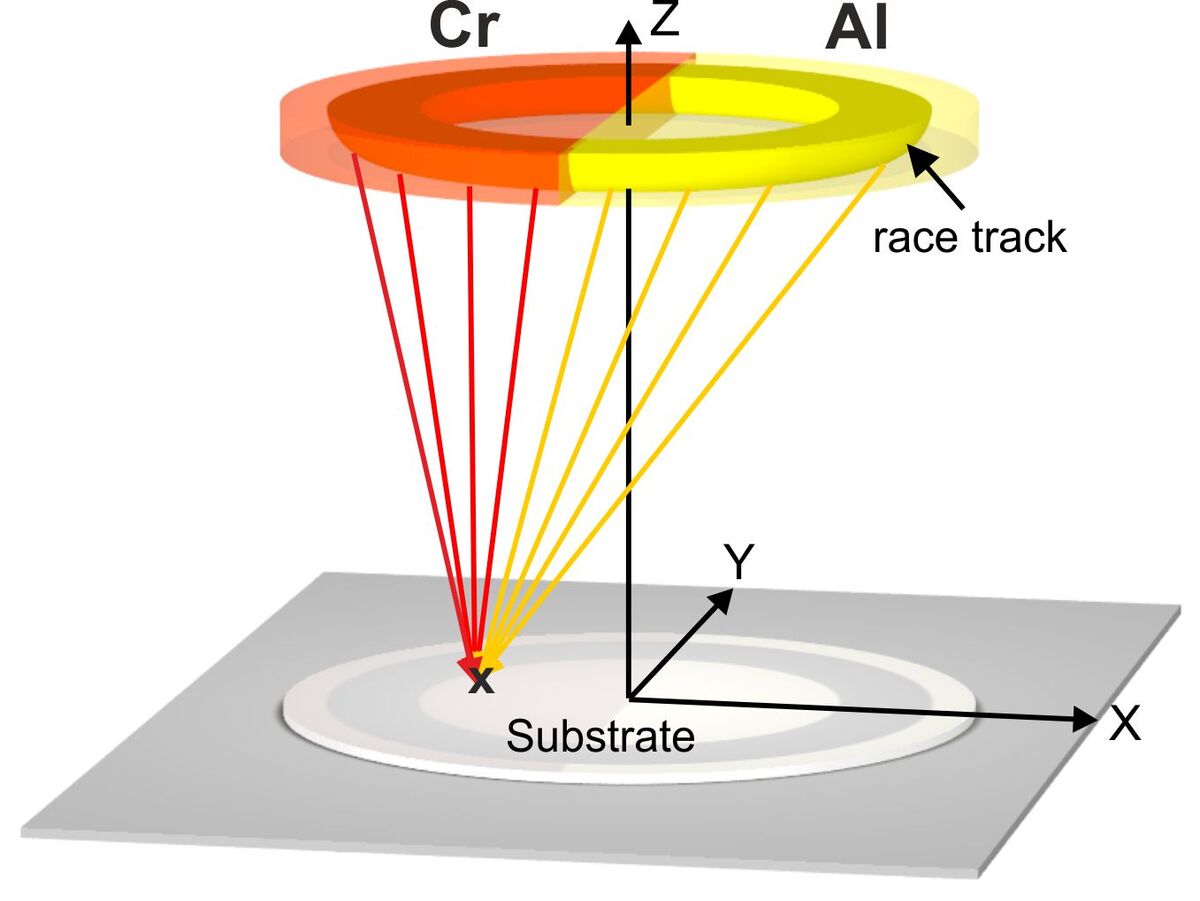

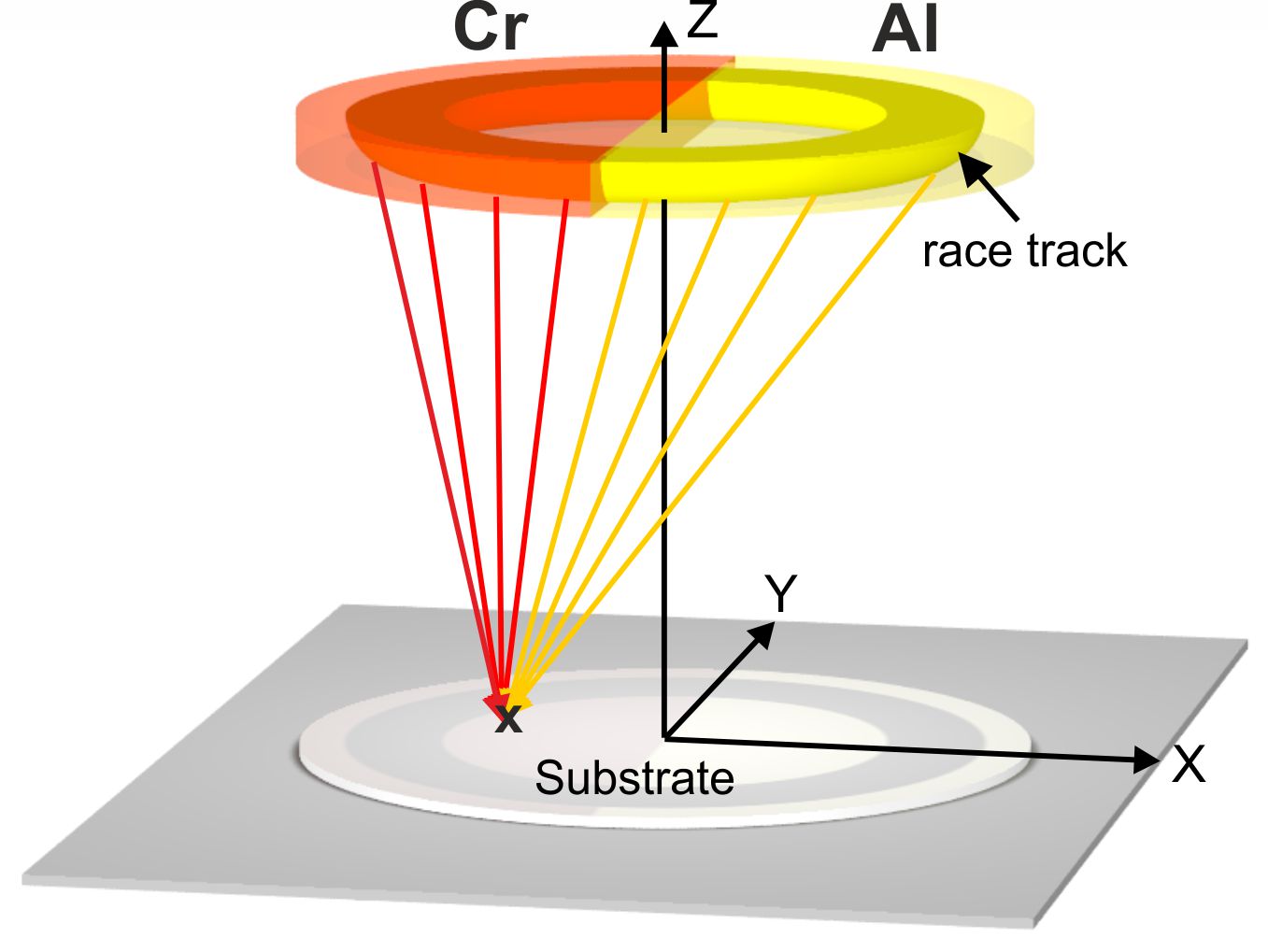

Schematic of the deposition geometry. Each point r = (X,Y) on the substrate surface receives material sputtered from the racetrack of both target segments. This results in a two-dimensional composition gradient which is strongest along the X axis. We have investigated Cr–Al–N coatings with a lateral composition gradient, using the combinatorial approach to screen the microstructure over a wide composition range. Two-dimensional thickness and composition profiles were determined nondestructively from X-ray fluorescence maps. They were reproduced by simulations of the flux distribution on the sample surface, combining TRIDYN simulations of the reactive sputter process at the target surface and SIMTRA simulations of the subsequent transport through the gas phase.

The phase formation was studied by spatially resolved X-ray diffraction, and X-ray absorption spectroscopy at the Cr K edge. For c ≲ 0.69, a single-phase solid solution f.c.c. (Cr,Al)N phase was found, and for 0.69 ≲ c ≲ 0.87 coexisting f.c.c. (Cr,Al)N and h.c.p. (Cr,Al)N phases were observed.

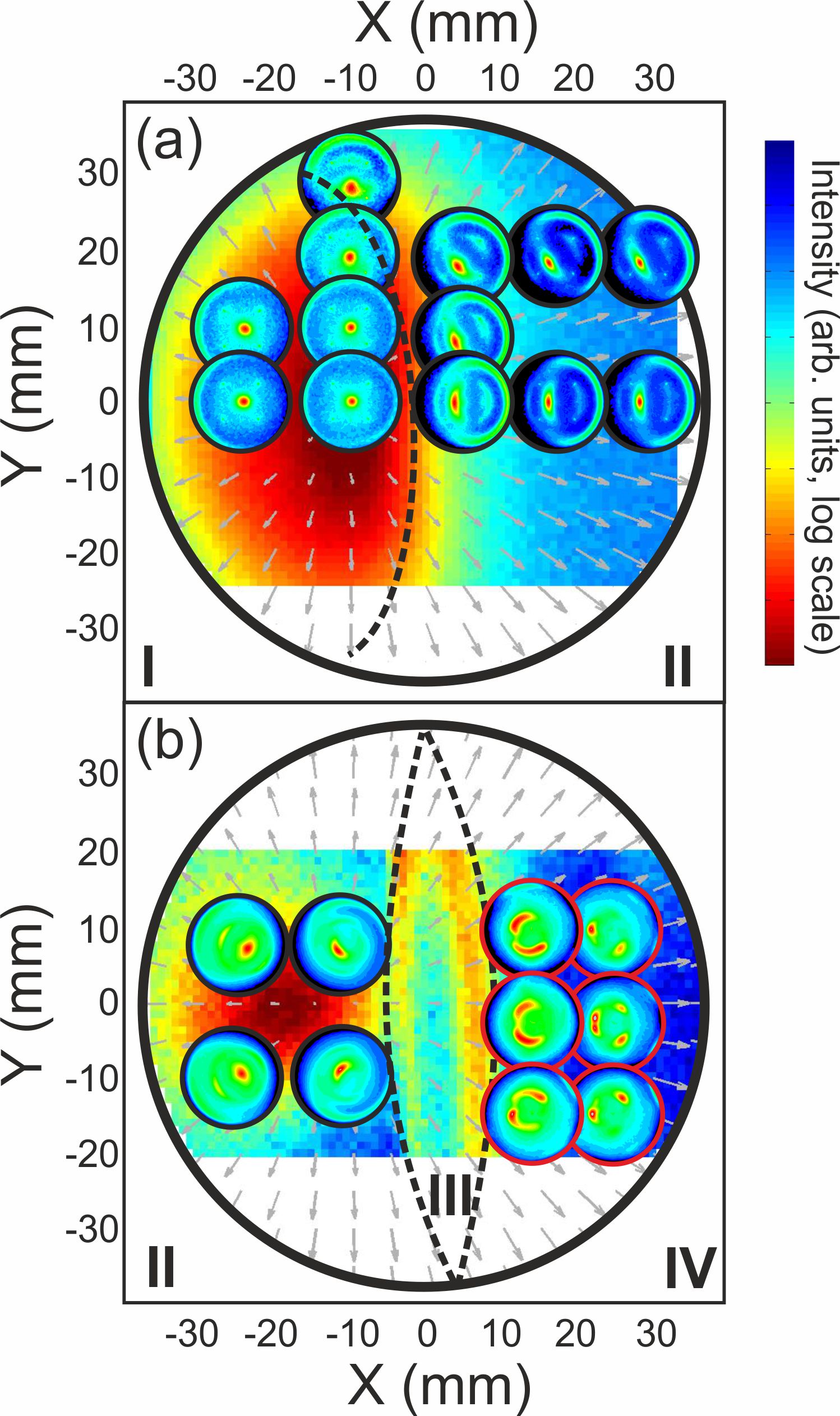

Directional alignment of the textures: selected f.c.c.(200) and h.c.p.(100) pole figures, measured at different sample positions for (a) the symmetric target and (b) the asymmetric target (thick coating). The intensity of the pole figures is shown in log scale, optimized for the respective intensity range of each pole figure. The f.c.c. pole figures are marked by a black circle and the h.c.p. pole figures by a red circle. In the background, a map of the diffuse scattering is shown (log scale), superposed by arrows indicating the average direction of the local particle flux (calculated from the SIMTRA simulations). The dashed lines indicate the borders between different texture zones. The biaxial texture formation in nearly the entire composition range indicates a zone T growth. Four, mainly composition-dependent, texture regions were identified. All observed textures are closely related to textures reported for the h.c.p. AlN and f.c.c. CrN parent phases. For c ≳ 0.69, a strong thickness dependence of the textures was observed. The measurements reveal an orientation relation between different f.c.c. and h.c.p. textures, indicating that local epitaxy might play a role in the structure formation.

B. Krause et al., Theoretical and experimental study of the gradient properties and the resulting local crystalline structure and orientation in magnetron-sputtered CrAlN coatings with lateral composition and thickness gradient, J. Appl . Cryst., 50 (2017) 1000-1010, https://doi.org/10.1107/S1600576717006513